Custom T-shirt Maker in Vietnam

Meet Paul, the owner of Un-Available sewing factory in Vietnam. I interviewed him in this video. His factory makes contemporary mens fashion. I can introduce you to Paul and many other good factories like his. Or you can contact Paul directly via LinkedIn. He is one of the best custom t-shirt makers in Vietnam.

My name is Chris. I have been working in the Vietnam Garment Industry since 2008. My expertise is advising fashion start-ups and sourcing factories. I built this website to promote Paul and Vietnam. Read more about Paul below.

My name is Chris. I have been working in the Vietnam Garment Industry since 2008. My expertise is advising fashion start-ups and sourcing factories. I built this website to promote Paul and Vietnam. Read more about Paul below.

Un-Available sews and screen prints under the same roof. The owners originally came to Vietnam to source manufacturing for their own t-shirt brand and they immediately encountered cultural differences which they have mastered over the years. They eventually built their own factory that produces for their own brand and others like Supreme, Palace and Saturdays. If you want to work with the best custom t-shirt maker in Vietnam that produces quality-on-time in small quantity with exemplary customer service then contact the owner. His name is Paul and he is a custom t-shirt maker in Vietnam.

Un Available is a sewing factory in Vietnam that specializes in both knit and woven streetwear apparel. The owners originally came to Vietnam to source manufacturing for their own t-shirt brand and they immediately encountered cultural differences which they have mastered over the years. They eventually built their own factory that produces for their own brand and others like Supreme, Palace and Saturdays. If you want to work with the best custom t-shirt maker in Vietnam that produces quality-on-time in small quantity with exemplary customer service then pull back the curtains and start the drum roll.

Un Available is a sewing factory in Vietnam that specializes in both knit and woven streetwear apparel. The owners originally came to Vietnam to source manufacturing for their own t-shirt brand and they immediately encountered cultural differences which they have mastered over the years. They eventually built their own factory that produces for their own brand and others like Supreme, Palace and Saturdays. If you want to work with the best custom t-shirt maker in Vietnam that produces quality-on-time in small quantity with exemplary customer service then pull back the curtains and start the drum roll.

Would you like to see a custom t-shirt factory in Vietnam?

Imagine that you have an idea to produce custom screen printed tees in Vietnam. Would it be great to get inside the sewing or printing factory to see how they print and sew? Would you like to check the quality yourself? I can get you inside Vietnamese high quality t-shirt factories for a tour. Watch my video for more details.

Services I Offer

eBooks

Courses

Consultation

Factory Introductions

Factory Tours

Production A to Z

When is a good time to schedule a time to talk?

Please fill in our contact form below,

then click the submit button.

See you in Vietnam!

Schedule a Factory Tour Today!

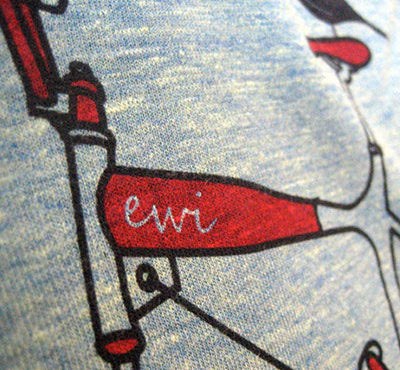

Marshall Artist is the name of Paul's brand

and they started it in London in 2001. They quickly became one of the UK’s most loved menswear brands. They aimed to create modern tailoring for modern people, producing contemporary, relevant clothing that is wearable, but also showcases British eccentricity. After producing a few seasons of both knit and woven styles ranging from wind runners to board shorts they were ready to start producing for other brands in Vietnam.Un Available management spends a lot of time and energy understanding and adapting to Vietnamese culture to constantly improve efficiency, lower costs and add value to their clothing manufacturing business. For example, in Vietnamese culture the junior staff are brought up to be submissive. They wait to be told what to do. At Un Available, the staff is trained to be pro-active and speak up regardless of age or position. To this day, the management focuses on hiring and training staff that is open to adapting to a western way of working. Un Available encourages staff to take ownership in the work they do. This is what makes them one of the best custom t shirt maker in Vietnam.

The cornerstone of the Un Available culture is responsibility. They have developed processes and systems that clearly define individual accountability. When one person has a particularly productive day they get kudos on the spot. If one staff is not pulling their weight then management pinpoints the problem and implements corrective action quickly. Every action in the manufacturing process is transparent; that transparency breeds accountability. This is how Un Available has overcome cultural differences and is the most reliable premium custom t shirt maker in Vietnam employing a western way of working from top management to factory floor staff.

Paul's Accountability Culture

From Un Available’s point of view as a brand they saw a gap in the market for small quantity full service apparel manufacturing. They identified the weakness of Vietnam being clear communication and ownership in design, development, sourcing and customer service. They became a custom t-shirt maker in Vietnam and committed to Vietnam when Vietnam was hungry for new business. They caught the wave early and successfully navigated the culture to become the best street wear fashion producer in Vietnam that can produce both knit and woven fashion garments with an MOQ of 250 pieces per style per color - under one roof. Their culture of accountability has lead to a momentum that will last for many years to come. Get a piece of the action in Vietnam by working with Un Available to produce your custom t shirts that can pass Japanese quality control standards and meet your tight deadlines.This is a photo of Paul's factory, he is a custom t-shirt maker in Vietnam that has 20+ years of experience.

How about you?

Are you a fashion start-up that is exploring production in Vietnam?Or, are you an established brand that needs help connecting with good factories in Vietnam? Either way I can help. Contact me. Let me introduce you to a custom t-shirt maker in Vietnam.

Water Based Screen Printing in Vietnam

Water-based inks are not only a good alternative to plastisol inks but they serve their own unique purpose as well. Water-based inks are great for jobs where you might require a high end vintage look with a soft feel. As mentioned earlier, plastisol isn't a great choice for these jobs. Another quality of water-based ink systems is that they seep into the fabric of the material being printed on instead of hardening over the top. This has a semi-transparent look to it which is great for that worn in print look.

Some of the strengths of water-based inks can also be it's weaknesses. This type of ink is more expensive to buy than plastisol and it's usually tougher to use. It's definitely slightly less user-friendly. Because the ink seeps into the fabric it's more semi-transparent which makes it very hard to print on dark garments. For that same reason, layering also becomes an issue. I know a custom t-shirt maker in Vietnam that has solved this problem.

Crack and Distress Printing in Vietnam

Printwear online magazine has a great article talking about crack and distress screen printing. The article explains how to create a layer in photoshop that is like a watermark. The watermark lays over the image and creates the distressed look. It explains how to set up the screen specifically for this type of screen printing.

To process crack and distress printing in Vietnam, they use special water base ink to print on bright color fabric. If your fabrics are dark, you must use rubber ink as opposed to water based. After printing, screen printers dry the fabric carefully to get the desired distressed look or let them dry at room temperature.

Crack and distress printing in Vietnam can be used on cotton spandex and polyester fabric. Its drying temperature is between 100 and 120 Celsius. It can be washed lightly in cold water.

This printing technology has 2 disadvantages: Low heat resistance and low durability. Heat resistance is lower than 100 degrees Celsius so they cannot be ironed. Crack and distress printing does not last well and can react with strong solvents and detergents used with washing machines.

Crack and Distress Screen Printing in Vietnam

Crack & Distress Printing in Vietnam involves the use of crack-ink. This kind of ink after printing and drying produces fracture surfaces which would look like cracks in the rock. This brings forth a weakness of crack & distress printing in Vietnam that the material would feel hard and rough.

Are you ready to meet a custom t-shirt maker in Vietnam?

Crack and Distress Printing in Vietnam is a screen printing technology many silk screen companies can do well. It is a popular embellishment for graphic t-shirts and many printers in Vietnam can do it.

Printwear online magazine has a great article talking about crack and distress screen printing.The article explains how to create a layer in photoshop that is like a watermark. The watermark lays over the image and creates the distressed look. It explains how to set up the screen specifically for this type of screen printing.

To process crack and distress printing in Vietnam, they use special water base ink to print on bright color fabric. If your fabrics are dark, you must use rubber ink as opposed to water based. After printing, screen printers dry the fabric carefully to get the desired distressed look or let them dry at room temperature.

Are you ready to meet a custom t-shirt maker in Vietnam?

Crack and distress printing in Vietnam can be used on cotton spandex and polyester fabric. Its drying temperature is between 100 and 120 Celsius. It can be washed lightly in cold water.

This printing technology has 2 disadvantages: Low heat resistance and low durability. Heat resistance is lower than 100 degrees Celsius so they cannot be ironed. Crack and distress printing does not last well and can react with strong solvents and detergents used with washing machines.

Main characteristics of crack & distress printing in Vietnam includes: Not durable, does not last well with strong solvents and other harsh cleaners.

Crack & Distress Printing in Vietnam requires washes with cold water and ordinary detergent. Strong bleaching solutions is not advised to use on products with crack & distress printing.

Heat resistance requirement of crack & distress printing in Vietnam is less than 100ºC, avoid ironing directly on the printed image.

Hanh Dan is the best company that can help you to do crack and distressed screen printing in Vietnam.

Printwear online magazine has a great article talking about crack and distress screen printing.The article explains how to create a layer in photoshop that is like a watermark. The watermark lays over the image and creates the distressed look. It explains how to set up the screen specifically for this type of screen printing.

To process crack and distress printing in Vietnam, they use special water base ink to print on bright color fabric. If your fabrics are dark, you must use rubber ink as opposed to water based. After printing, screen printers dry the fabric carefully to get the desired distressed look or let them dry at room temperature.

Are you ready to meet a custom t-shirt maker in Vietnam?

Crack and distress printing in Vietnam can be used on cotton spandex and polyester fabric. Its drying temperature is between 100 and 120 Celsius. It can be washed lightly in cold water.

This printing technology has 2 disadvantages: Low heat resistance and low durability. Heat resistance is lower than 100 degrees Celsius so they cannot be ironed. Crack and distress printing does not last well and can react with strong solvents and detergents used with washing machines.

Main characteristics of crack & distress printing in Vietnam includes: Not durable, does not last well with strong solvents and other harsh cleaners.

Crack & Distress Printing in Vietnam requires washes with cold water and ordinary detergent. Strong bleaching solutions is not advised to use on products with crack & distress printing.

Heat resistance requirement of crack & distress printing in Vietnam is less than 100ºC, avoid ironing directly on the printed image.

Hanh Dan is the best company that can help you to do crack and distressed screen printing in Vietnam.

Photo Screen Printing in Vietnam

Spot color printing uses a full range of color to create an image on a garment. Each color of the image is printed separately on its own screen. Thus it is expensive. However, using spot color printing can help you to print 8 to 12 different spot colors exactly on one location. In addition, using this technique can help you to reach a higher level of color consistency for your artwork.

May I introduce you to a custom t-shirt maker in Vietnam?

Spot color screen printing can actually be more expensive than process printing because it requires complex artwork and many screens. Moreover it can produce excellent image but it requires printer experience in artwork creation.

Spot color printing works well with 100% cotton fabrics and 100% polyester fabrics. It can be print on garment with unlimited color. Its dry temperature is about 140 degree Celsius. Spot color printing T-shirt is durable. You cannot iron directly on the image printing. You can learn about emulsion for photo screen printing on Instructables website.

Printing photograph like scenery and portrait on garments is popular in Vietnamese screen printing industry. The technique that is used is called spot color printing, as opposed to using CMYK technique in the past.

Spot color screen printing uses a full range of color to create an image on a garment. Each color of the image is printed separately on its own screen. Thus it is expensive. However, using spot color printing can help you to print 8 to 12 different spot colors exactly on one location. In addition, using this technique can help you to reach a higher level of color consistency for your artwork.

Spot color screen printing can actually be more expensive than process printing because it requires complex artwork and many screens. Moreover it can produce excellent image but it requires printer experience in artwork creation. Are you ready to contact a custom t-shirt maker in Vietnam?

Spot color screen printing uses a full range of color to create an image on a garment. Each color of the image is printed separately on its own screen. Thus it is expensive. However, using spot color printing can help you to print 8 to 12 different spot colors exactly on one location. In addition, using this technique can help you to reach a higher level of color consistency for your artwork.

Spot color screen printing can actually be more expensive than process printing because it requires complex artwork and many screens. Moreover it can produce excellent image but it requires printer experience in artwork creation. Are you ready to contact a custom t-shirt maker in Vietnam?

Photo screen printing is an alternative to digital printing. Edgar at Nantex knows how to do both. He sells and services screen printing equipment that employs the CMYK method that is required for photo screen printing. He also knows direct to garment and sublimation digital printing. He is very familiar with the Kornit and Epson DTG printers.

Spot color screen printing uses a full range of color to create an image on a garment. Each color of the image is printed separately on its own screen. Thus it is expensive. However, using spot color printing can help you to print 8 to 12 different spot colors exactly on one location. In addition, using this technique can help you to reach a higher level of color consistency for your artwork.

Spot color screen printing can actually be more expensive than process printing because it requires complex artwork and many screens. Moreover it can produce excellent image but it requires printer experience in artwork creation.

Spot color screen printing works well with 100% cotton fabrics and 100% polyester fabrics. It can be print on garment with unlimited color. Its dry temperature is about 140 degree Celsius. Spot color printing T-shirt is durable. You cannot iron directly on the image printing.

Spot color screen printing uses a full range of color to create an image on a garment. Each color of the image is printed separately on its own screen. Thus it is expensive. However, using spot color printing can help you to print 8 to 12 different spot colors exactly on one location. In addition, using this technique can help you to reach a higher level of color consistency for your artwork.

Spot color screen printing can actually be more expensive than process printing because it requires complex artwork and many screens. Moreover it can produce excellent image but it requires printer experience in artwork creation.

Spot color screen printing works well with 100% cotton fabrics and 100% polyester fabrics. It can be print on garment with unlimited color. Its dry temperature is about 140 degree Celsius. Spot color printing T-shirt is durable. You cannot iron directly on the image printing.

Silicone Screen Printing in Vietnam

Silicone screen printing is one of the most expensive printing technology in Vietnam. However, it is the most preferable choice of many famous brands in the world.

The process of silicone printing in Vietnam is like normal printing technology. However printers use silicone ink instead of water base ink. It is made of carbon, hydrogen, oxygen and silicon atoms as well as other ingredients. It is highly elastic so the silicone printing can be stretched and then returns to its original shape. Are you ready to meet a custom t-shirt maker in Vietnam?

The process of silicone printing in Vietnam is like normal printing technology. However printers use silicone ink instead of water base ink. It is made of carbon, hydrogen, oxygen and silicon atoms as well as other ingredients. It is highly elastic so the silicone printing can be stretched and then returns to its original shape. Are you ready to meet a custom t-shirt maker in Vietnam?

Silicone printing works well with 100% cotton fabrics, 100% polyester fabrics, 15% spandex fabrics and denim fabrics.

The new silicone ink in Vietnam does not contain phthalate, formaldehyde or PVC so they are friendly with workers, customers and the environment. Drying temperature is from 120 to 150 degree Celsius. It has high heat resistance so you can iron it directly without destroying the print. Moreover, a silicone printing garment has an excellent durability. It can stand all wash tests.

Using silicone ink to print on garment make the garment look bright, soft and durable. It is highly glossy and has great flexibility as well as excellent durability. Therefore it is still used by many screen printing manufacturer in Vietnam although its cost is more expensive than other printing technology. Dow Corning is an expert in silicon screen printing and silicone inks. Check out their website if you have any questions.

The new silicone ink in Vietnam does not contain phthalate, formaldehyde or PVC so they are friendly with workers, customers and the environment. Drying temperature is from 120 to 150 degree Celsius. It has high heat resistance so you can iron it directly without destroying the print. Moreover, a silicone printing garment has an excellent durability. It can stand all wash tests.

Using silicone ink to print on garment make the garment look bright, soft and durable. It is highly glossy and has great flexibility as well as excellent durability. Therefore it is still used by many screen printing manufacturer in Vietnam although its cost is more expensive than other printing technology. Dow Corning is an expert in silicon screen printing and silicone inks. Check out their website if you have any questions.

Silicon Screen Printing in Vietnam

Main characteristic of Silicon Screen Printing in Vietnam are that it is reliable, could be adversely impacted by strong solvents and other harsh cleaners.

Types of Printed fabric that produces the best results of Silicon Screen Printing in Vietnam is 100% Cotton, 100% Polyester, Spandex, Waterproofing Nylon and Denim.

Drying temperature required for Silicon Screen Printing in Vietnam is from 120ºC to 150ºC.

Silicon Screen Printing in Vietnam can withstand all wash tests.

Silicon Screen Printing in Vietnam can last up to very high heat. Printed images can be ironed directly without ill effects.

Do you want to see the real effect of silicone screen printing? Check out this video.

The process of silicone screen printing in Vietnam is like normal printing technology. However printers use silicone ink instead of water base ink. It is made of carbon, hydrogen, oxygen and silicon atoms as well as other ingredients. It is highly elastic so the silicone printing can be stretched and then returns to its original shape. Silicone screen printing works well with 100% cotton fabrics, 100% polyester fabrics, 15% spandex fabrics and denim fabrics.

The new silicone ink in Vietnam does not contain phthalate, formaldehyde or PVC so they are friendly with workers, customers and the environment.

Drying temperature is from 120 to 150 degree Celsius. It has high heat resistance so you can iron it directly without destroying the print. Moreover, a silicone-printing garment has an excellent durability. It can stand all wash tests.

Using silicone ink to print on garment make the garment look bright, soft and durable. It is highly glossy and has great flexibility as well as excellent durability. Therefore it is still used by many screen printing manufacturer in Vietnam although its cost is more expensive than other printing technology.

The new silicone ink in Vietnam does not contain phthalate, formaldehyde or PVC so they are friendly with workers, customers and the environment.

Drying temperature is from 120 to 150 degree Celsius. It has high heat resistance so you can iron it directly without destroying the print. Moreover, a silicone-printing garment has an excellent durability. It can stand all wash tests.

Using silicone ink to print on garment make the garment look bright, soft and durable. It is highly glossy and has great flexibility as well as excellent durability. Therefore it is still used by many screen printing manufacturer in Vietnam although its cost is more expensive than other printing technology.

Services I Offer

Consulting

Factory Introductions

Design and Development

A - Z Sublimation Garment Production